Introduction

Overhead power lines play a crucial role in transmitting electricity from power plants to homes, businesses, and industries. However, rubber sheathed flexible cable can pose significant safety hazards if not properly grounded. Grounding is essential to protect people, equipment, and infrastructure from electrical faults and lightning strikes. In this article, we will explore the importance of overhead power line grounding and delve into various techniques used to ensure the safety and reliability of power distribution systems.

Importance of Overhead Power Line Grounding

Grounding is a fundamental aspect of electrical systems design, especially in overhead power line installations. Proper grounding serves multiple purposes, including:

1. Safety: Grounding helps to protect people and equipment from electrical shock hazards. By providing a low-resistance path to the earth, grounding ensures that fault currents are safely diverted away from the system components and personnel.

2. Lightning Protection: Overhead power lines are susceptible to lightning strikes, which can cause significant damage to the infrastructure and disrupt power supply. Proper grounding helps to dissipate the energy from lightning strikes and reduce the risk of equipment damage and power outages.

3. System Performance: Effective grounding minimizes the risk of voltage surges, electromagnetic interference, and other disturbances that can affect the performance and reliability of the power distribution system.

4. Compliance: Regulatory standards and codes mandate the proper grounding of overhead power lines to ensure compliance with safety requirements and prevent accidents and liabilities.

Grounding Techniques for Overhead Power Lines

Various grounding techniques are employed in overhead power line installations to achieve the desired level of safety and reliability. These techniques include:

1. Grounding Electrodes: Grounding electrodes are metallic rods or plates that are buried in the ground near the base of the power line poles. These electrodes provide a low-resistance path for fault currents to dissipate into the earth. Common types of grounding electrodes include copper-clad steel rods, galvanized steel rods, and concrete-encased electrodes.

2. Grounding Grids: Grounding grids consist of interconnected conductors buried in a grid pattern beneath the power line structures. The grid enhances the effectiveness of grounding by providing a larger surface area for current dissipation and reducing ground resistance. Grounding grids are commonly used in high-voltage transmission lines and substations.

3. Tower Grounding: Tower grounding involves connecting the metallic structure of the power line towers to grounding electrodes or grids. This ensures that any lightning strikes or fault currents are safely diverted to the ground, protecting the tower structure and the equipment mounted on it.

4. Surge Arresters: Surge arresters are protective devices installed at strategic locations along the power line to mitigate voltage surges caused by lightning strikes or switching operations. Surge arresters divert the excess energy to the ground, preventing damage to the equipment and ensuring the continuity of power supply.

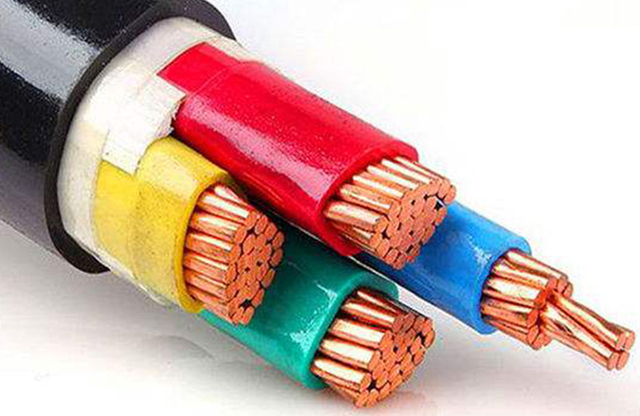

5. Grounding Conductors: Grounding conductors are metallic cables or wires that connect the various components of the power line system to the grounding electrodes or grids. These conductors provide a low-impedance path for fault currents and ensure effective grounding throughout the system.

6. Ground Fault Protection: Ground fault protection devices are installed in the power line system to detect and isolate faults that could pose a safety hazard. These devices monitor the current flow and trip the circuit breaker or disconnect switch in case of a ground fault, preventing damage to the equipment and ensuring personnel safety.

7. Soil Resistivity Testing: Soil resistivity testing is conducted to determine the electrical resistivity of the soil at the grounding site. This information is crucial for designing an effective grounding system that minimizes ground resistance and maximizes the efficiency of current dissipation.

8. Maintenance and Testing: Regular maintenance and testing of the grounding system are essential to ensure its continued effectiveness. Periodic inspections, soil resistivity measurements, and testing of grounding electrodes help identify any issues and make necessary adjustments to maintain the integrity of the grounding system.

Case Studies and Best Practices

Let's look at a few case studies and best practices related to overhead power line grounding techniques:

1. Lightning Protection for Transmission Lines: In a case study conducted by a utility company, the installation of grounding grids and surge arresters along high-voltage transmission lines significantly reduced the incidence of equipment damage and power outages caused by lightning strikes. The comprehensive grounding system improved the reliability of the power transmission network and minimized maintenance costs.

2. Tower Grounding in Substations: A best practice in substation design is to ensure proper tower grounding by connecting the metallic structures to grounding electrodes and grids. This practice helps to protect the substation equipment from lightning strikes and fault currents, ensuring the safety of personnel and preventing damage to critical infrastructure.

3. Ground Fault Protection in Distribution Networks: Implementing ground fault protection devices in distribution networks has proven to be effective in preventing electrical accidents and minimizing equipment damage. By detecting ground faults early and isolating the affected circuits, these devices improve the safety and reliability of the power distribution system.

Conclusion

In conclusion, overhead power line grounding is a critical aspect of ensuring the safety and reliability of power distribution systems. By employing a combination of grounding techniques, including grounding electrodes, grids, tower grounding, surge arresters, and ground fault protection, electrical utilities can mitigate safety hazards, protect equipment from damage, and maintain the continuity of power supply. Regular maintenance, testing, and adherence to regulatory standards are essential to ensure the effectiveness of the grounding system. By implementing best practices and learning from case studies, utilities can enhance the performance of their overhead power line grounding systems and provide a safe and reliable electricity supply to consumers.

References:

1. IEEE Guide for Safety in AC Substation Grounding (IEEE Std 80-2013).

2. IEC 62305-1:2010 Protection against lightning – Part 1: General principles.

3. "Grounding and Bonding for the Electrical Systems" by IEEE Industry Applications Society.

4. "Grounding Systems in the Electrical Substation" by CIGRE Technical Brochure 55.

5. "Lightning Protection of Overhead Power Lines" by IET Engineering Technical Report 48.

By implementing the best practices and techniques discussed in this article, electrical utilities can ensure the safety and reliability of their overhead power line systems, contributing to the efficient and uninterrupted supply of electricity to consumers.